What is Roof Decking?

A roof deck covers the surface of a roof between the structural components (joists and trusses), insulation, and waterproofing layers (coatings, roof materials, layers, etc.). There are two types of roof deck: the roof deck and the roof deck. In order to overcome this challenge, it must be able to hold weight while also maintaining durability.

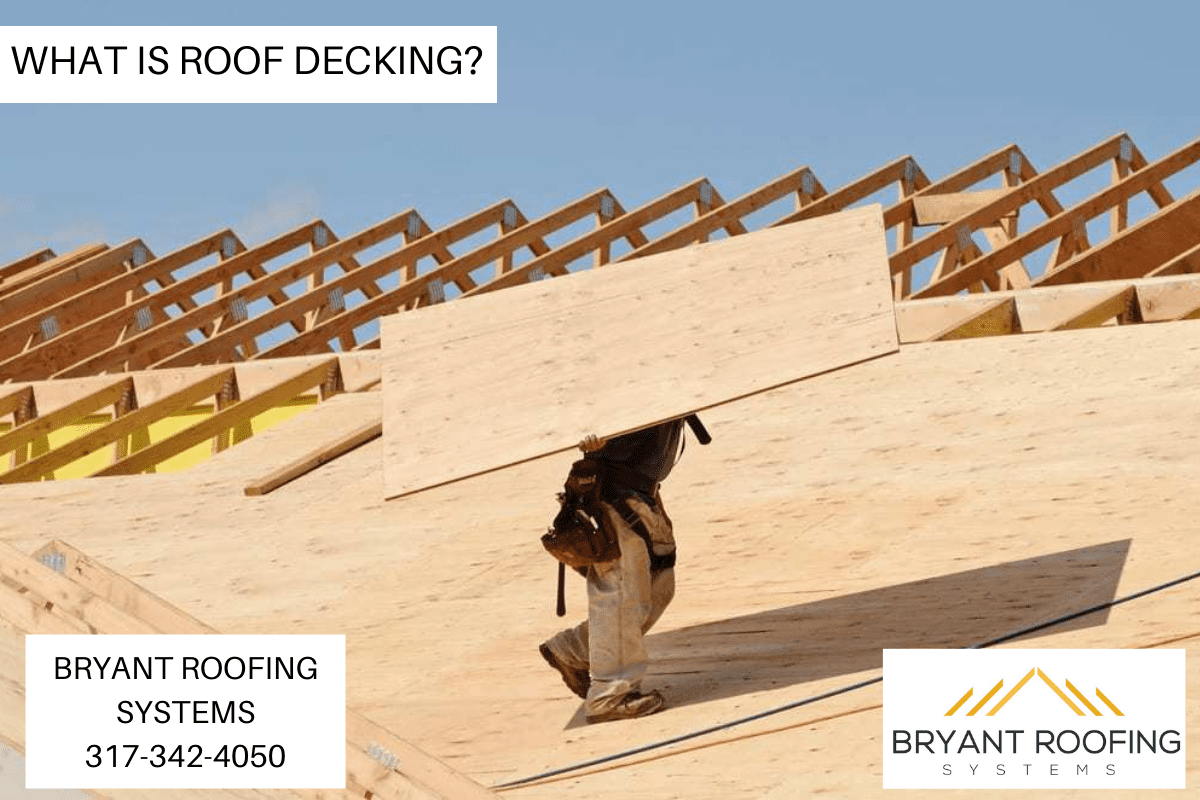

Roof decking, also called roof sheathing, is the foundation of your roofing system that connects the roof to your house. A roof deck is a base above the structural trusses, which form the foundation of your attic, and the decking supports the roof shingles.

Other factors include the weight of any air conditioning equipment, rainfall in the area, and any potential buildup of snow. The residence may also need special features like walking decks or rooftop swimming pools or bars for extra support.

Roof decking can be made from various materials. Wood, cement, concrete, steel, and more can be found in these materials. Based on the amount of weight that it has to carry, the type of material is chosen. The type of roof decking materials is based on whether there is a commercial or residential roof. Residential homes will most likely use wood for the roof sheathing because the wood used generally can sustain the weight materials used for the roof replacement.

Common Roof Decking Materials

Concrete Roof Decking

Concrete roof decking is when a solid piece of concrete is used to seal off the top of your home. When using solid concrete, there are a few different varieties that you can use.

Structural Concrete

This type of normal weight concrete is usually used for cast-in-place construction and is an important part of the entire structure. It is designed to handle really heavy loads and is usually topside insulated using insulation panels.

Structural Concrete Composite

This type of concrete decking is usually used as part of a building design when a future above the roof level is possible. It is a steel panel deck system that contains structural lightweight or normal weight concrete.

Lightweight Insulating

When using this kind of concrete, it is common to place it on a variety of structural deck systems constructed to handle heavyweight. It is low-density, lightweight, non-structural concrete that can be used directly on a properly supported corrugated steel deck system.

Types of Wood Roof Decking

Zip Wood

This kind of wood is a created product that is most famous for its durability and strength. One of the unique factors of zip wood is using a water-resistant barrier that is still able to breathe. This type of barrier removes the requirement of roofing felt. Every layer of the zip system is extremely moisture resistant, making this material a solid choice for decking.

FRT Plywood

FRT is short for Fire – Retardant – Plywood and is usually required by building codes to prevent fires from spreading from one home to another. This material, however, may not be the best material to use since building inspectors discovered that less than reputable contractors built numerous housing units with faulty FRT Plywood in the '80s. The FRT plywood used from years ago could degrade before its time and often results in roof replacements.

CDX Plywood

This type of Plywood gets its durability from many layers of wood being combined into one. The grain of this wood changes from layer to layer, adding to the durability of the entire piece of Plywood. CDX is a popular type of Plywood for roof decking because it can withstand moisture and even some exposure to rain.

Benefits of Steel Roof Decking

Lightweight

This type of material is extremely lightweight, which is a huge plus when considering metal decking. Compared to concrete or tile, there is no contest when it comes to weight.

Durable

Using metal as decking material will also give you a very durable roof. This material is much tougher and resistant to hail and other elements that come your way. This material has also been graded by the insurance commissions in the U.S to have the top level of impact resistance for roofing materials. Some insurance companies will even give you a discount if you have metal decking.

Low Energy Costs

During the hot summer months, this kind of material can reflect the heat a lot more than any other kind of roofing material. Ultimately, this means the heat in your home is greatly reduced, which means the energy bill comes down.

Types of Roof Decking

Tongue and groove roof decking is also known as plywood, OSB sheathing or plank sheathing. Knowing what to expect from each type of roof decking will help you make an informed decision.

Tongue and Groove

A tongue and groove deck is typically constructed with a 2x6 "tongue" on one edge of the board. The tongue fits into a groove on the adjacent board; the groove is meant to fit snugly. The problem with this is that it's not easily available at most lumberyards.

Roof decking of this type is generally highly durable and strong. Repairs are only necessary if it has been exposed to water for an extended period of time. If you are going over tongue and groove decking, make sure to take your time.

Plywood or OSB Sheathing

If you are familiar with plywood or OSB sheathing, you may have seen it before under the false term Wafer Board. This method is strong and resists splitting. These methods were popularized in the 1980s and 1990s, and are still used almost exclusively by builders.

The installation process should be guided by a few points. Lay the boards vertically using staggered joints and align them to the ridgeline. The vertical joints between the boards have to be supported along the whole length and need to be nailed securely.

It is also important to ensure sufficient support with an absolute maximum of 600 mm between the two rafters. Your roof replacement company should install those plywood panels with 3 mm spacing between each panel unless stated differently by the manufacturer.

Plank Sheathing

Plywood, on the other hand, is more common than plank sheathing. Wood shingles tend to be expensive when it comes time to tear down and replace them, so using re-sheathing over the entire roof is a far cheaper method.

Because of weather changes, plank sheathing tends to distort. Those planks will wear down over time because of constant expansion and contraction, causing them to become brittle if this occurs enough. Furthermore, staggering your joints is essential. A deck may shift when several adjacent boards are attached to the same support or rafter. All the wood boards used have to be properly conditioned to be at a moisture equilibrium.

It should also have a sufficient number of fasteners to keep it from buckling, and each board should be nailed to the rafter at least two times so that the boards stay fastened firmly but without too much effort.

Benefits of New Roof Decking

Brand new roof decking spreads out all the weight over your entire home, which can reinforce your roof to handle things like severe weather or even fallen branches.

Another benefit is that decking is a secondary line of defense against any leaks or moisture. While shingles will handle most protection against water, it always helps to have a little more help. While Plywood is flammable, modern flame retardants are applied to the wood to give extra defense against flames. You never know when these different scenarios can happen, so it's better to replace your decking now if it's needed.

Protecting Your Roof

Roof decks are generally meant to hold fasteners for securing the roof. You can count on it to withstand foot traffic and the occasional snow load, which will become a part of any roof. Depending on the condition of the wood, the roof may not be able to withstand its suggested lifetime.

A good roof deck is essential for any roofing system. The deck is designed to absorb gravity loads, lateral winds, and seismic forces. Proper roof decking must meet all design requirements, including component anchorage, fire resistance, and surface characteristics.

Property owners should be concerned about the condition of the deck and the design. Here are some of the reasons.:

- Condition of the roof deck

- Stability

- Resistance

- Removal

- PV Panels

Signs a Roof Deck Needs to Be Replaced

Most roofs are built to last about 20 years, although the actual lifespan varies depending on the materials, quality of the installation, and the local climate. A metal roof installation can last a lifetime. Another thing that can lead to damaged roof decking is excessive interior moisture caused by insufficient venting in the attic. If you need to replace your roof decking, there are certain signs. Signs that you need to replace roof decking are as follows:

- Leaky roof

- Stained Walls

- Sagging ceiling

- Holes

- Roof mold

- Damage around flashing or chimneys

- Significant changes in heating or cooling bills

How to Fix Wooden Roof Sheathing Problems

Make certain to properly ventilate your attic to eliminate any excess moisture that deck panels can absorb. Clearing out excess moisture reduces the shrinking and swelling that the wood experiences, helping it last for longer without becoming increasingly brittle and ultimately breaking.

When the wooden roof decking has brittleness, the structural integrity of your roof will be compromised, which will require you to fix or replace it as soon as possible to prevent accidents from happening.

However, it would be best if you made certain that the roof decking is installed properly so that the weight of your roof is supported properly. Take any additional snow weight if your area sees heavy snowfall so that your deck does not bow and crack under additional pressure.

Unbeknownst to most, like your building foundation, roof decking is the foundation of the rest of the new roof replacement. Without proper roof decking, your roof's foundation will fail and then buckle under the pressure, causing a need for a roof replacement.

Save Time and Money with the Proper Roof Deck

You will save yourself a lot of time and effort by making sure the foundation of your roof, the roof decking, has been properly installed and is rated to handle the weight of your roof materials. Call the Indianapolis roof replacement specialists, Bryant Roofing Systems, at 317-342-4050 or email us at service@bryantroofs.com.

Get Your 24-Hour Estimate

$500 OFF

COMPLETE THIS FORM TO CLAIM $500 OFF YOUR QUALIFYING ROOF JOB

317-342-4050service@bryantroofs.comMon – Fri: 8:00 – 05:30